Wood bending

The technique of wood bending is an ancient method, present in the craftsmanship of various civilizations, but it remained in the background for a long time due to its limited productivity advantages.

The technique

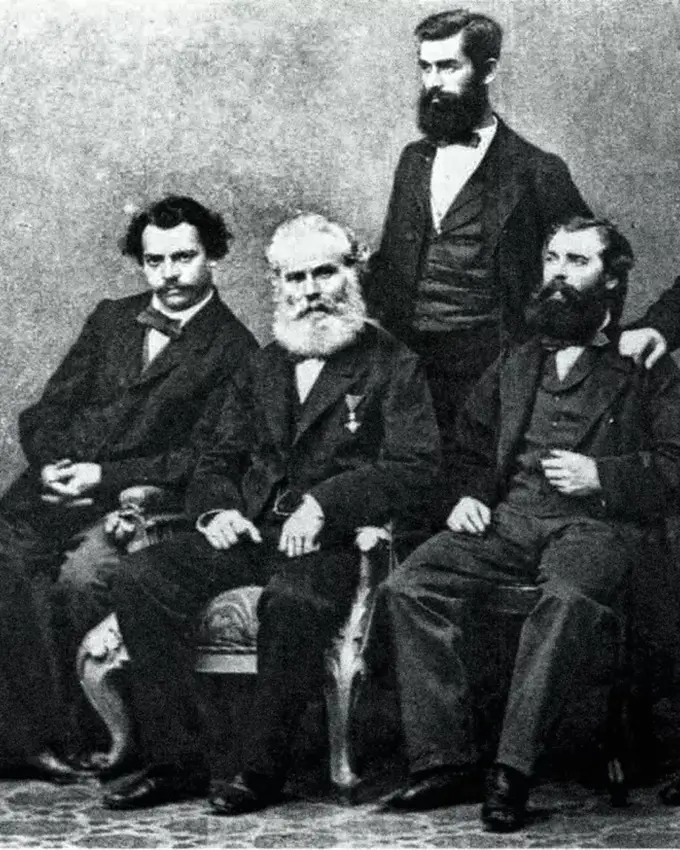

Michael Thonet’s intuition came from the observation that fresh wood is more flexible than dry wood. Based on this observation, Thonet and some of his contemporaries experimented with bending bundles of thin sheets of wood, immersed in boiling glue, and then dried in rigid molds.

However, this solution did not guarantee the product’s durability due to the fragility of the adhesive. To overcome this problem, Thonet decided to work exclusively on the physical properties of the wood, completely eliminating glue from his processes. To achieve greater flexibility of the material – even after aging – he increased the sliding between the fibers by exposing them to a highly humid environment.

The patent

In 1842, Michael Thonet patented the process that made him famous worldwide: strips of wood (preferably beech, due to its long, regular fibers and lack of knots) were turned, placed in an autoclave to absorb moisture, bent with force, and fixed in metal molds, before being dried. After finishing the pieces, the “Vienna straw” was assembled, a distinctive element of the company.

A true industrial process, accompanied by the progressive elimination of ornaments and joints, in favor of strict lines and greater simplification of assembly elements.

Formal elegance, solidity, and lightness ensured the company’s success, which in just a few years opened production facilities worldwide. A unique production method, rooted in a history full of inspirations, which today renews itself through the choice of high-quality materials. The woods, selected for their strength and versatility, are combined with fine fabrics, enriching the collection with refined color shades.